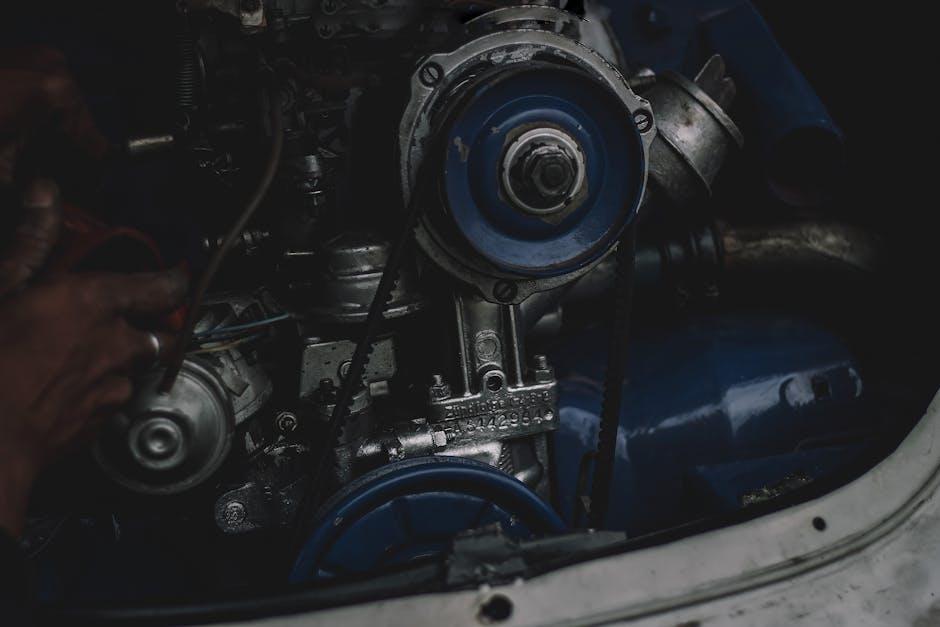

Beneath the roar of a car’s engine lies a complex symphony of moving parts, each playing a crucial role in delivering power and performance. Over time, wear and tear can dull this harmony, leading to sluggishness or failure. When replacement isn’t the only or best option, there’s a process that breathes new life into these mechanical hearts: the engine rebuild. But what exactly does an engine rebuild entail? In this article, we’ll unravel the layers of this meticulous craft, exploring how expert hands restore worn engines to their former glory, and what that means for drivers and their vehicles.

Table of Contents

- Understanding the Core Purpose of an Engine Rebuild

- Key Components Involved in the Rebuilding Process

- Signs Your Engine Might Need a Rebuild Soon

- Step-by-Step Overview of How an Engine Rebuild Is Performed

- Choosing Between an Engine Rebuild and Replacement

- Expert Tips for Maintaining a Rebuilt Engine for Longevity

- Q&A

- Concluding Remarks

Understanding the Core Purpose of an Engine Rebuild

An engine rebuild serves as a comprehensive restoration process aimed at reviving the heart of a vehicle—the engine. Over time, wear and tear cause critical components like pistons, rings, bearings, and valves to degrade, impairing performance and fuel efficiency. Instead of replacing the entire engine, a rebuild focuses on disassembling, cleaning, repairing, and replacing parts to bring the engine back to its original or near-original condition. This approach is not only cost-efficient but also a sustainable choice, extending the lifespan of your engine while maintaining the vehicle’s reliability.

At its core, this process addresses several key objectives that go beyond just fixing issues:

- Restoring Power: Ensures the engine delivers the intended horsepower and torque.

- Enhancing Efficiency: Improves fuel consumption by optimizing engine condition.

- Reducing Emissions: Minimizes harmful exhaust output through proper sealing and combustion.

- Preventing Breakdowns: Replaces worn parts to avoid unexpected engine failures.

- Preserving Vehicle Value: A well-maintained engine maintains resale worth and driving confidence.

| Component | Rebuild Task | Benefit |

|---|---|---|

| Pistons & Rings | Replace with new or recondition | Improved compression and performance |

| Bearings | Check & replace if worn | Smoother engine rotation |

| Valves | Clean, grind, or replace | Better airflow and combustion |

| Gaskets & Seals | Replace all | Prevents leaks and pressure loss |

Key Components Involved in the Rebuilding Process

When diving into the intricate world of engine rebuilding, several critical components play a pivotal role in restoring your engine’s performance and longevity. Among these, the pistons stand out as vital elements, converting fuel combustion into mechanical motion. Alongside them, the cylinder walls need careful honing or replacement to ensure a smooth interaction with piston rings, which seal combustion gases and maintain compression. Equally essential are the crankshaft and connecting rods, which work in tandem to translate piston movement into rotational energy, driving the vehicle forward.

Beyond these primary parts, several supporting components contribute to the overall success of the rebuild. Valves, camshafts, and timing chains influence air and fuel flow, impacting engine efficiency and power output. To ensure precise function, new gaskets and seals are installed, preventing leaks and preserving internal pressure. The table below highlights these key components along with their primary functions during the rebuilding process:

| Component | Function |

|---|---|

| Pistons | Convert combustion into movement |

| Cylinder Walls | Maintain compression and reduce friction |

| Crankshaft | Transforms piston reciprocation into rotation |

| Valves | Regulate air-fuel mixture and exhaust flow |

| Gaskets & Seals | Prevent leaks and maintain pressure |

Signs Your Engine Might Need a Rebuild Soon

When your engine starts showing signs of distress, it’s a clear signal that a major overhaul might be on the horizon. Some common indicators include excessive smoke from the exhaust, unusual knocking noises, or a significant drop in performance and fuel efficiency. You might also notice oil contamination, frequent overheating, or blue/white smoke, all pointing towards internal wear and tear. Ignoring these warnings could lead to costly repairs, so keeping an eye on these symptoms can save you from unexpected breakdowns.

Below is a quick guide to help you identify potential problems early on:

- Excessive Oil Consumption: Needing to add oil often means worn piston rings or valve seals.

- Knocking or Tapping Sounds: Could indicate damaged bearings or worn engine components.

- Compression Loss: Leads to sluggish response and reduced power output.

- Visible Smoke: Blue or white smoke can hint at burning oil or coolant leaks.

- Overheating Issues: Might be caused by worn out gaskets or blocked coolant passages.

| Symptom | Possible Cause | Urgency |

|---|---|---|

| Oil Leakage | Worn seals or gaskets | Medium |

| Engine Knock | Worn bearings or pistons | High |

| Blue Exhaust Smoke | Burning oil | High |

| Loss of Power | Compression issues | Medium |

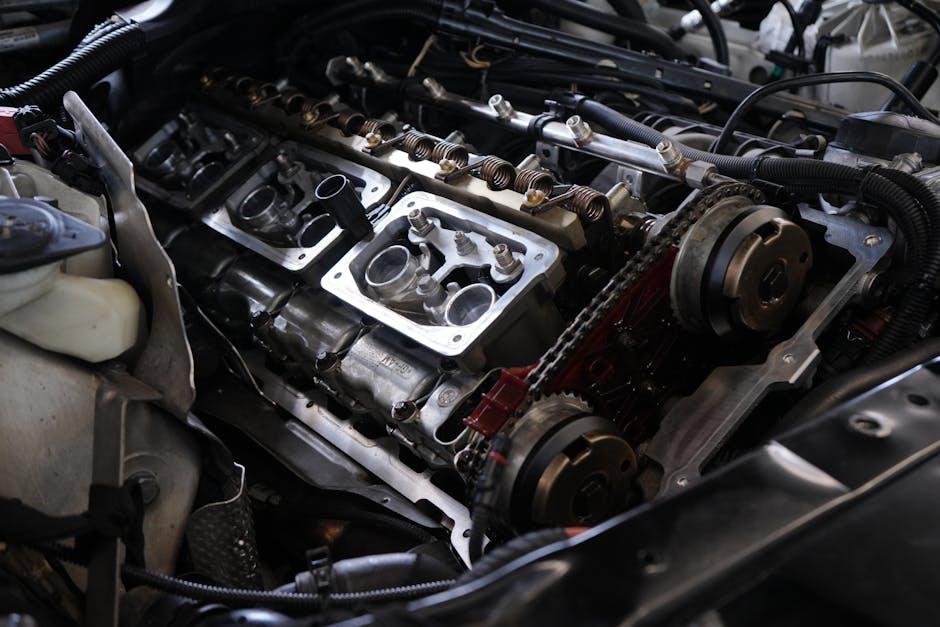

Step-by-Step Overview of How an Engine Rebuild Is Performed

Rebuilding an engine is a meticulous process that breathes new life into an aging powerhouse. It begins with a thorough disassembly where every component is carefully removed and inspected. Mechanics pay close attention to the condition of critical parts like pistons, crankshafts, and cylinder walls, determining which elements need replacement or refurbishing. Once stripped down, the cleaning phase eliminates years of deposits, making way for precision measurements to assess wear and tear. This diagnostic step is crucial to customize the rebuild, ensuring every fit and clearance meets exacting standards.

Following assessment, the engine is reassembled with a mix of refurbished and new parts. The process involves:

- Replacing worn components such as gaskets, seals, and bearings to restore sealing and motion

- Re-machining critical surfaces like cylinder heads or block decks for smooth contact and compression

- Rebalancing moving parts to minimize vibrations and optimize performance

- Lubrication system checks to ensure proper oil flow and longevity

Precision testing after assembly guarantees the engine operates within manufacturer specifications, ready to deliver power and efficiency anew.

Choosing Between an Engine Rebuild and Replacement

Deciding whether to opt for an engine rebuild or a replacement involves carefully weighing your vehicle’s condition, budget, and long-term goals. An engine rebuild is ideal when the core components are still salvageable but require restoration to perform efficiently again. This process involves disassembling the engine, cleaning and inspecting parts, and replacing worn elements like pistons, rings, bearings, and gaskets. It’s a cost-effective choice that retains most of your original engine, making it perfect if the damage is moderate and you’re looking to extend your engine’s life without the expense of a full replacement.

On the other hand, replacing the engine completely is often the best option when severe damage, extensive wear, or outdated technology compromises performance and reliability. While more costly upfront, a new engine can offer the benefits of improved fuel efficiency, reduced emissions, and a longer warranty period. Consider these factors when evaluating your options:

- Cost comparison: Rebuilds typically cost less but vary based on parts needed.

- Timeframe: Rebuilds can take longer depending on engine complexity.

- Vehicle age and value: A replacement may be more sensible for older cars with lower value.

- Performance expectations: Replacements might be necessary for high-performance upgrades.

| Factor | Engine Rebuild | Engine Replacement |

|---|---|---|

| Typical Cost | Lower | Higher |

| Turnaround Time | Longer | Shorter |

| Warranty | Limited | Extended |

| Suitability | Moderate wear | Severe damage |

Expert Tips for Maintaining a Rebuilt Engine for Longevity

Proper care after rebuilding an engine is crucial to ensure it performs optimally and enjoys an extended lifespan. One of the most vital practices is regular oil changes using high-quality synthetic oil, specifically recommended for rebuilt engines. New components need clean, consistent lubrication to settle and wear evenly. Additionally, it’s wise to run the engine at moderate speeds for the first 500 miles—this break-in period helps the newly machined surfaces properly mate without undue stress. Avoiding rapid accelerations and high RPMs during this stage cannot be overstated.

Beyond break-in, maintaining longevity also means embracing routine maintenance and monitoring crucial systems. Keep an eye on the cooling system; overheating can quickly undo the benefits of a rebuild. Check and replace air filters frequently to prevent contaminants from abrasive wear inside the engine. Consider these expert tips for longevity:

- Use engine flush additives periodically to keep internal passages clean.

- Inspect spark plugs for signs of oil or carbon deposits; replace them as needed.

- Monitor engine compression every 20,000 miles to detect potential wear early.

| Maintenance Task | Recommended Interval | Purpose |

|---|---|---|

| Oil & Filter Change | Every 3,000 – 5,000 miles | Protect new engine components |

| Coolant Check | Every 10,000 miles | Prevent overheating |

| Compression Test | Every 20,000 miles | Assess engine health |

Q&A

Q: What exactly is an engine rebuild?

A: An engine rebuild is a comprehensive process where a vehicle’s engine is disassembled, cleaned, inspected, repaired, and reassembled to restore it to good working condition. Think of it as giving your engine a second life by replacing worn-out parts and fine-tuning components to ensure optimal performance.

Q: Why would someone need an engine rebuild?

A: Over time, engines endure wear and tear from everyday use—parts can degrade, seals may leak, and performance drops. When issues like low compression, excessive oil consumption, or strange noises crop up, an engine rebuild can fix these problems and prevent a full engine replacement.

Q: How is an engine rebuild different from an engine repair?

A: Repairs typically fix specific, isolated issues—like swapping out a faulty gasket or replacing spark plugs. A rebuild, however, is more extensive, involving a complete teardown and overhaul of many engine parts to address multiple issues and extend the engine’s lifespan.

Q: What parts are usually replaced or refurbished during a rebuild?

A: Commonly, pistons, rings, bearings, gaskets, seals, and sometimes cylinder heads or camshafts are rebuilt or replaced. The goal is to return internal components to “like-new” condition, ensuring smooth and efficient engine operation.

Q: How long does an engine rebuild take?

A: The timeline varies widely depending on the engine’s size, condition, and complexity of needed repairs. It can be anywhere from a few days to several weeks. Patience pays off as a thorough rebuild often means fewer problems down the road.

Q: Is an engine rebuild cost-effective compared to buying a new engine?

A: Generally, yes. Rebuilding an engine tends to be less expensive than purchasing a new or remanufactured engine, especially when labor and shipping costs are considered. Plus, it lets you preserve your vehicle’s originality.

Q: Can any engine be rebuilt?

A: Most engines can be rebuilt, but feasibility depends on factors like availability of parts, extent of damage, and overall cost. Sometimes, if damage is too severe or parts are rare, replacement might be a better option.

Q: What are the benefits of choosing an engine rebuild?

A: A rebuild can improve fuel efficiency, restore lost power, eliminate burning oil or strange noises, and extend your engine’s life. It’s an eco-friendly choice too, as it reduces waste compared to buying entirely new engines.

Q: Should I attempt to rebuild my engine myself?

A: Unless you have advanced mechanical skills, specialized tools, and a clean workspace, it’s best left to professionals. Engine rebuilding requires precision and expertise to ensure everything fits and functions perfectly.

Q: How do I know when it’s time for an engine rebuild?

A: Signs include decreased performance, knocking or ticking noises, smoke from the exhaust, excessive oil consumption, or engine warning lights. A trusted mechanic can diagnose and advise whether a rebuild is the best course of action.

Concluding Remarks

In the intricate dance of pistons and valves, an engine rebuild is more than just a mechanical reset—it’s a meticulous revival of power and precision. Whether sparked by wear, damage, or the desire to extend a vehicle’s life, this process breathes new vigor into an aging heart of metal. Understanding what an engine rebuild entails not only demystifies the craft but also highlights the blend of engineering skill and patience it demands. So next time you hear the rhythmic hum of a finely tuned engine, remember that beneath its steady pulse lies the story of careful restoration and renewed potential.