Brakes are the unsung heroes of every journey, quietly ensuring our safety mile after mile. At the heart of this vital system lie the brake rotors—those sturdy discs that bear the brunt of every stop. But like any hardworking component, rotors have their limits, wearing down over time and use. Knowing when to replace your brake rotors isn’t just about maintaining smooth rides; it’s about safeguarding your control on the road. In this article, we’ll explore the key signs and timing that signal it’s time to swap out your rotors, helping you stay both informed and secure behind the wheel.

Table of Contents

- Understanding the Role and Lifespan of Brake Rotors

- Signs Your Brake Rotors Are Ready for Replacement

- How Driving Habits Influence Brake Rotor Wear

- Assessing Rotor Thickness and Surface Condition

- Choosing Quality Replacement Rotors for Optimal Performance

- The Importance of Professional Inspection and Timely Rotor Replacement

- Q&A

- To Wrap It Up

Understanding the Role and Lifespan of Brake Rotors

Brake rotors are integral to your vehicle’s braking system, acting as the surface against which brake pads clamp down to bring your car to a stop. They are designed to withstand immense heat and friction, but over time, this wear and tear can compromise their efficiency and safety. As they age, rotors may develop issues like warping, scoring, or thinning, each of which affects braking performance and vehicle control.

Recognizing when rotors need replacement can save you from costly repairs or dangerous situations. Here are some common signs:

- Vibrations through the steering wheel during braking

- Squealing or grinding noises when applying the brakes

- Visible grooves or cracks on the rotor surface

- Brake pedal pulsation during stops

| Rotor Condition | Common Symptom | Recommendation |

|---|---|---|

| Warped | Steering vibrations | Replace immediately |

| Excessively thin | Reduced braking power | Replace before next inspection |

| Scored | Noise during braking | Resurface or replace |

Signs Your Brake Rotors Are Ready for Replacement

Recognizing when your brake rotors are due for a change can save you from costly repairs and, more importantly, keep your rides safe. If you notice a consistent vibrating or pulsating feeling through the brake pedal or steering wheel while braking, it’s a classic indication that your rotors could be warped. Uneven rotor surfaces also often reveal themselves as scraping or squealing noises, which can be caused by grooves or cracks formed from excessive wear or heat damage.

Other subtle signs might seem unrelated but are critical red flags: your vehicle may start pulling to one side when braking, or you could experience reduced braking responsiveness. Pay close attention to the following symptoms:

- Visible scoring or grooves on rotor surface

- Increased brake pad wear without obvious cause

- Rust buildup that doesn’t wear off easily

- Thinning rotors below manufacturer specifications

| Symptom | What It Means | Recommended Action |

|---|---|---|

| Vibration in pedal | Warped or uneven rotors | Inspect and resurface or replace rotors |

| Squealing noise | Grooves or metallic contact | Brake system inspection needed |

| Pulling during braking | Uneven rotor thickness | Replace affected rotors |

| Thin rotor edges | Worn beyond safe limits | Immediate rotor replacement |

How Driving Habits Influence Brake Rotor Wear

Your daily driving style plays a significant role in how quickly brake rotors wear down. Aggressive braking, such as sudden stops and frequent hard braking, generates excessive heat and friction, which can cause the rotors to warp or develop grooves over time. Conversely, a more controlled and gradual approach to slowing down lessens the stress on your braking components, extending the lifespan of your rotors. Urban driving with constant stop-and-go traffic tends to wear rotors faster compared to highway driving, which usually involves steady speeds and minimal braking.

Consider these key factors influencing brake rotor wear during your drives:

- Driving Terrain: Hilly or mountainous terrain demands more braking effort, accelerating rotor wear.

- Brake Frequency: More frequent stops mean more friction and faster deterioration.

- Load Weight: Heavier loads put additional pressure on rotors, shortening their effective life.

- Driving Speed: Higher speeds can increase heat buildup during braking, affecting rotor integrity.

| Driving Habit | Effect on Rotor Wear | Typical Rotor Lifespan Impact |

|---|---|---|

| Aggressive Braking | High heat & friction causes warping | Reduced by 30-40% |

| Steady, Gradual Braking | Minimal heat, less wear | Extended by 20-30% |

| Stop-and-Go Traffic | Frequent friction leads to grooves | Reduced by 25-35% |

| Highway Cruising | Less frequent braking; cooler rotors | Extended by 15-25% |

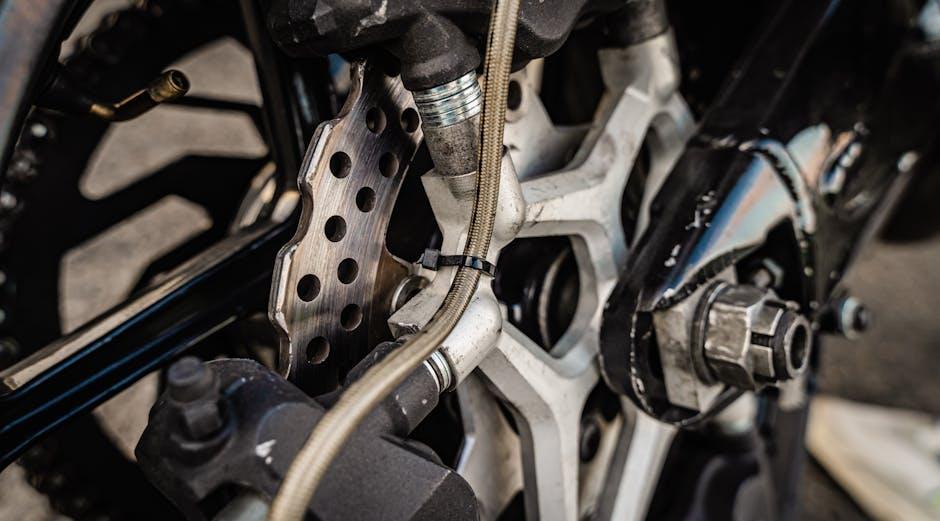

Assessing Rotor Thickness and Surface Condition

One of the most crucial steps in maintaining your vehicle’s braking system is regularly checking how much material remains on your brake rotors. Over time, rotors wear down due to constant friction from the brake pads, and if they become too thin, they risk failing under pressure. Most manufacturers specify a minimum thickness, often engraved or stamped on the rotor’s edge. Using a micrometer or brake rotor gauge, measure the rotor at several points around its surface to get an accurate assessment. If the rotor thickness approaches or falls below the manufacturer’s minimum specification, it’s time to consider a replacement to maintain safe and efficient braking performance.

Surface condition plays an equally vital role as thickness when deciding whether to replace your rotors. Look out for deep grooves, warping, cracks, or rust buildup, all of which can compromise the rotor’s integrity and reduce braking efficiency. Uneven rotor wear can also cause vibrations when braking, which negatively affects control. Here’s a quick checklist of signs indicating rotor surface problems:

- Grooves or scoring: Excessive roughness or ridges

- Cracks: Small or significant fractures on the surface

- Warping: Rotors that cause steering wheel shimmy during braking

- Corrosion: Rust spots weakening the rotor material

| Condition | Effect on Braking | Recommended Action |

|---|---|---|

| Thickness Near Minimum | Reduced heat dissipation, risk of rotor cracking | Replace immediately |

| Scored Surface | Uneven wear, noisy braking | Resurface or replace depending on severity |

| Warped Rotor | Brake pedal pulsation and vibration | Replace recommended |

| Rust and Corrosion | Weakens rotor structure, reduces pad contact | Assess severity; replace if extensive |

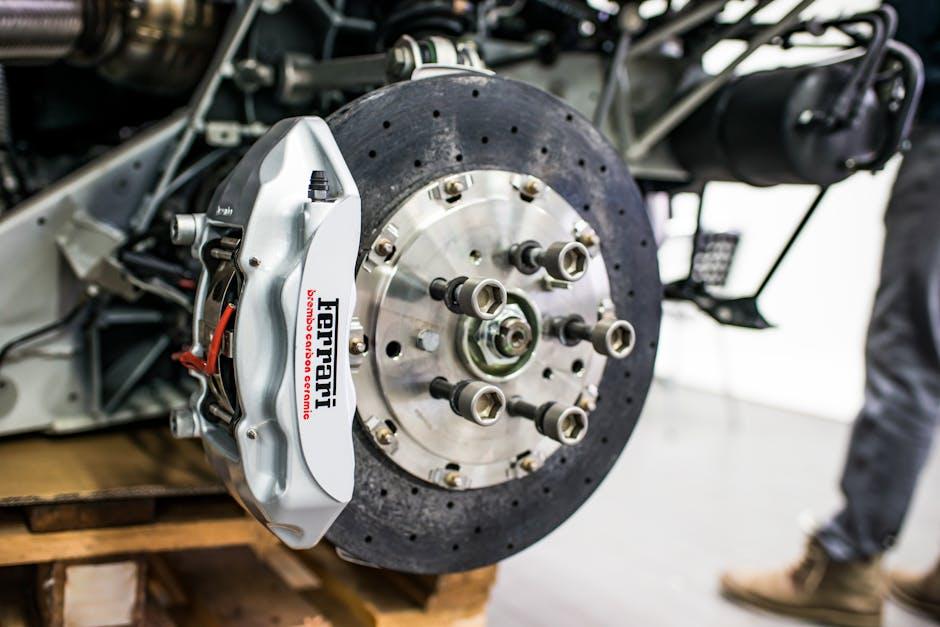

Choosing Quality Replacement Rotors for Optimal Performance

When selecting replacement rotors, the mark of quality lies not just in brand reputation but in the material composition and manufacturing precision. Opting for high-grade alloys that resist warping and corrosion ensures longevity and consistent braking力. Additionally, check for rotors with enhanced features such as cross-drilling or slotting, which aid in heat dissipation and improve wet-weather performance—key factors for maintaining control under demanding conditions.

It’s also vital to balance performance with practicality. Here’s a quick guide to help you weigh your options:

- Cast iron rotors: Durable and cost-effective but heavier and prone to rust.

- Composite rotors: Lightweight with better heat resistance, ideal for high-performance vehicles.

- Coated rotors: Added rust protection extends rotor life, especially in humid or salty climates.

| Rotor Type | Advantages | Best For |

|---|---|---|

| Standard Cast Iron | Affordable, strong | Daily driving |

| Drilled & Slotted | Improved cooling, better grip | Sporty driving and track use |

| Carbon Composite | Lightweight, superior heat management | High-performance vehicles |

The Importance of Professional Inspection and Timely Rotor Replacement

Ensuring your vehicle’s braking system performs optimally requires more than just routine maintenance; it demands a professional inspection to accurately assess the condition of your brake rotors. Skilled technicians utilize advanced diagnostic tools to detect subtle signs of wear such as warping, scoring, or thinning that are often invisible during a casual visual check. This level of expertise not only enhances safety but also protects your investment by preventing extensive damage to other brake components.

Timely rotor replacement is crucial to maintaining reliable stopping power and avoiding costly repairs. Consider these key indicators that warrant professional attention:

- Uneven brake pad wear

- Vibration or pulsation during braking

- Squealing or grinding noises

- Visual cracks or deep grooves on the rotor surface

Below is a quick reference guide outlining typical rotor thickness ranges and replacement thresholds, helping you understand when it’s time to take action:

| Rotor Type | Nominal Thickness (mm) | Minimum Thickness (mm) | Replacement Frequency |

|---|---|---|---|

| Standard | 22 | 20 | Every 50,000 miles |

| Performance | 28 | 25 | Every 40,000 miles |

Q&A

Q: How do I know it’s time to replace my brake rotors?

A: Signs your brake rotors need replacing include a pulsating brake pedal, unusual noises like squealing or grinding, visible grooves or cracks on the rotor surface, and reduced braking performance. If you feel a vibration or hear a high-pitched screech when braking, your rotors may be warped or worn out.

Q: Can I drive safely with worn-out brake rotors?

A: While you might still be able to drive, worn or damaged rotors can severely compromise your braking efficiency, putting you and others at risk. It’s best to address rotor issues promptly to ensure safe stopping distances.

Q: How often should brake rotors be replaced?

A: There’s no one-size-fits-all timeline; factors like driving habits, vehicle type, and rotor material affect longevity. Generally, rotors last anywhere from 30,000 to 70,000 miles, but regular inspections during brake servicing will provide the most accurate assessment.

Q: Can I replace just one rotor, or should I replace them in pairs?

A: It’s best practice to replace brake rotors in pairs (both front or both rear) to maintain balanced braking. Uneven rotor conditions between wheels can lead to uneven braking force and potentially unsafe handling.

Q: Is resurfacing an option instead of replacing the rotors?

A: Resurfacing (or turning) rotors can extend their life if the damage is minor and there’s enough material left to safely remove. However, if rotors are too thin, cracked, or heavily scored, replacement is the safer choice.

Q: What causes brake rotors to wear out faster?

A: Aggressive braking, driving in stop-and-go traffic, excessive heat from downhill driving, and poor-quality brake pads can accelerate rotor wear. Regular maintenance and mindful driving can help extend rotor life.

Q: How much does it typically cost to replace brake rotors?

A: Prices vary depending on vehicle type, rotor quality, and labor rates, but expect the cost per rotor replacement (including labor) to range from $150 to $300. Investing in quality rotors and professional installation helps ensure safety and longevity.

Q: Can I replace the rotors myself?

A: If you have experience with car maintenance and the right tools, rotor replacement can be a DIY project. However, brakes are critical to vehicle safety. If you’re uncertain, it’s wise to have a professional mechanic handle the job.

To Wrap It Up

Knowing when to replace your brake rotors is key to maintaining not only your vehicle’s performance but also your safety on the road. While the telltale signs of worn rotors—such as vibrations, strange noises, or noticeable grooves—should never be ignored, regular inspections can help catch issues before they escalate. By staying attentive to these signals and consulting with a trusted mechanic, you ensure that every stop is as smooth and secure as the drive itself. After all, brakes are your car’s unsung heroes—quietly working behind the scenes to keep you moving forward safely.